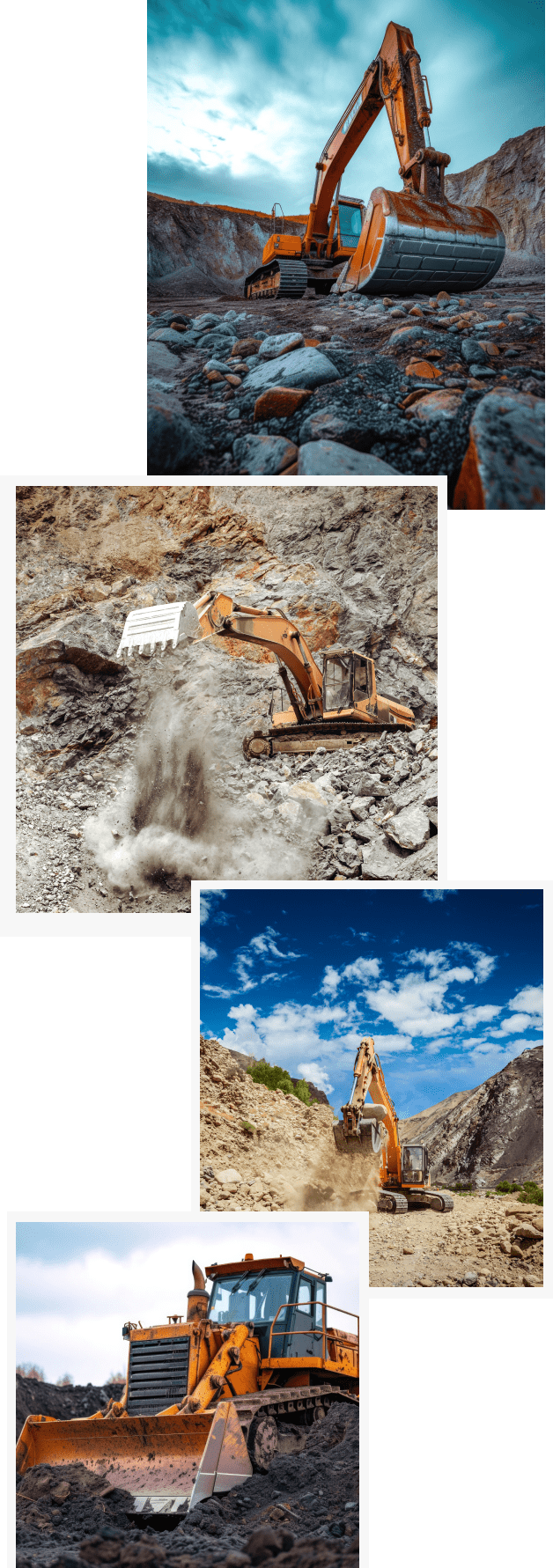

Entering the Indian market requires a deep understanding of local operating conditions and infrastructure standards. Uttam Blastech specialises in helping international companies navigate these complexities with ease. Our construction Excavation and engineering expertise ensures that your projects are completed on time, within budget, and to the highest safety and quality standards.

From the initial requirement of knowing the details of strata to be excavated and quantifying the Rock and Soil to be excavated to Seamless Excavation planning that is in sync with your project execution schedules and advising on the necessary Permissions required and documentation required to Sub Contractor’s evaluation to reviewing excavation progress and suggesting remedial measures to overcome the problems, Uttam is a one-stop solution for all your excavation knowledge needs.

Your Excavation and Planning Department is on call whenever you need it.

Comprehensive Rock and Soil Analysis:

Our Geologists and Geophysicist Team will quantify the Rock and types of Rock and the soil to be Excavated in your project using various Geological and Geophysical Techniques

Optimal Quarry Selection:

Quarrying can make or break some projects; hence, getting a suitable quarry at the right place is essential for the success of some projects.

At Uttam Blastech, our geologists and mining engineers with experience in mineral investigation ensure that you get the right quarry for your project at the right place.

Quarry section login www.uttamblastech.com

Quarry Selection case study https://uttamblastech.com/operating-a-quarry/

Strategic Excavation Planning:

Excavation is the first step in your execution. Any delay in excavation delays the entire project.

Uttam Blastech understands your excavation requirements, project schedules, and constraints and helps you plan excavation that is most suitable for you and takes the least time and with the utmost safety.

Efficient Quarry Planning:

Uttam uses the latest software for quarry planning and provides the best plan for quarrying with the least cost, highest safety and productivity and is legally compliant.

Excavation often involves Rock Excavation. Rock Excavation means the use of Explosives. Use of Explosives needs permissions and compliance as any misuse of explosives can have serious unwanted consequences.

Uttam ensures that the use of explosives at the project site is legally compliant and that you are protected against any claims of damage due to blasting.

Below is the checklist for your Excavation needs

Spanning more than two decades. When you procure from us, you get our product development and usage expertise.

Our team has over 200 years of combined experience in infrastructure, ensuring top-tier project management and innovative engineering solutions. We deliver robust, efficient projects that meet the highest quality and safety standards.

Our team has combined more than 200 years of experience in the industry and is the best in the industry, ensuring that you can bank upon our experience.

Congratulations, excavation is the first step of your project. Any delay in excavation may delay the entire project.

Uttam Blastech brings you a checklist to ensure that your excavation runs smoothly.

A. Did you do the Rock Classification studies properly? Do you know the quantities of Rock and Soil to be Excavated?

B. Did you select the Quarrying Areas?

1. Did you obtain all the permissions for quarrying?

2. Did you plan your quarries properly for the least cost, highest production and Safety?

B. Did you make your excavation and Quarrying plan consisting of

1. Final levels after excavation and existing ground levels.

2. Benches of excavation

3. Approach ramps

4. Dumping ground

5. Dump yards

6. Pumping arrangements

7. Slope protection

a. During excavation

b. After excavation

Please visit https://uttamblastech.com/knowledge-corner/excavation-planning/ to know more about excavation planning.

C. If excavation involves Rock

1. Is permission to possess and use explosives under explosives rules obtained?

2. Did you obtain permission from the Police and Law and Order Department to conduct blasting and use of explosives?

3. Is the Diameter of drilling most appropriate for your site requirements?

4. Are you using the right equipment for drilling?

5. Did you do a pre-blast survey of neighbouring properties to avoid litigation in future?

6. Are explosives being brought every day from the licensed magazine?

7. Are leftover explosives being returned to the magazine after use for that day?

8. Is a licensed van being used to transport explosives and accessories?

9. Are detonators and explosives being transported by separate vans?

10. Is 3rd party monitoring all the blasts for ground vibrations and noise so that there is a witness to prove your case in case of any issue or claim of damage?

Visit https://uttamblastech.com/knowledge-corner/blasting-damage/ to know more about use of explosives and blast damage.

D. To Know more about Blasting Related Litigation and how to face them

Visit https://uttamblastech.com/knowledge-corner/blasting-excavation-litigation/

E. Are you Hiring an Excavation Contractor.

Visit https://uttamblastech.com/knowledge-corner/contractors-evaluation/ to know more about contractor evaluation.

Copyright 2024, UTTAM BLASTECH PVT LTD, Hyderabad