Can your suppliers deliver on time?

Uttam Blastech guarantees timely delivery of stemming plugs, keeping your project on schedule.

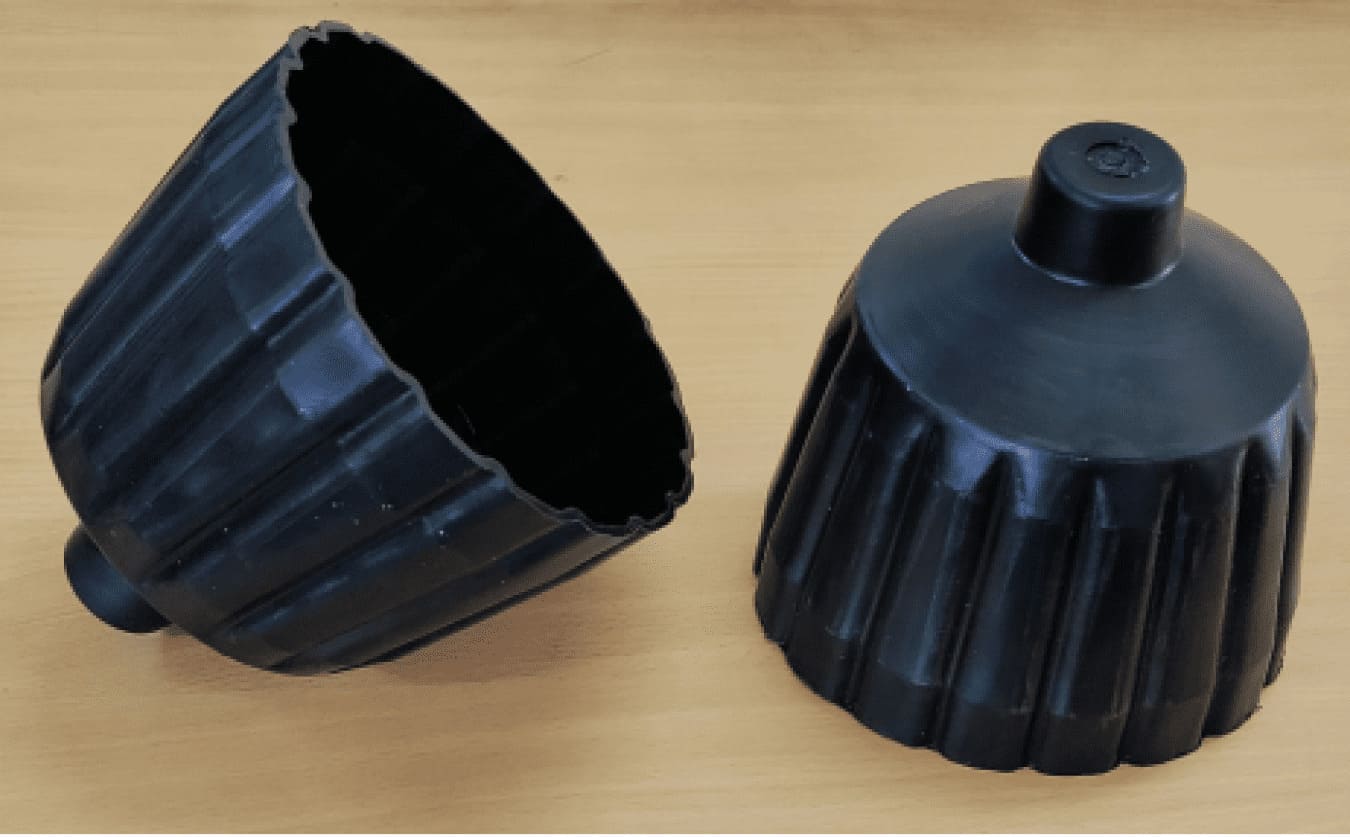

Is the product well-researched?

Uttam Blastech's stemming plugs are designed for safety and performance. They are made from high-quality materials, ensure a proper seal to direct explosive energy, and integrate seamlessly with detonation systems. They meet safety standards and offer good value for the cost.